Providing Last-Mile Delivery for Farmers across Sub-Saharan Africa

Being able to deliver goods and services directly to people in all corners of the world is something that has been growing in importance for many companies over the past few years. From office chairs to groceries, plants to DIY hardware, many of us can now get pretty much anything delivered directly to our front doors. The push for fast, direct delivery has only been accelerated by the COVID-19 pandemic as the majority of us were forced to stay at home.

In places like Sub-Saharan Africa, infrastructure challenges and the remoteness of many communities means that the delivery of goods and services directly to people comes with huge challenges. We’re seeing this with the roll-out of COVID vaccines where doses are being delivered to capital cities but often not making it much further. In instances like this, it takes innovative logistics solutions to get people the things they need. It’s this so-called ‘last mile’ of delivery that is so crucial to ensuring the hardest to reach people still get access to life’s necessities.

At One Acre Fund, we excel at last-mile delivery, distributing more than 90,000 tons of farm inputs within walking distance of farmer’s homes every year across six countries in Sub-Saharan Africa. Here, our delivery experts John Genga and Leah Atieno share One Acre Fund’s experience delivering life-changing products to more than a million farmers and share the lessons we have learnt along the way.

What is last-mile delivery, and why is it so important to what One Acre Fund does?

John: It is the very last step of the supply chain distribution process when products or goods move from storage hubs to their final destination. In the context of One Acre Fund, it is the last leg of a long journey that involves sourcing planting inputs (seeds and fertilizer) and non-crop products, such as solar lamps and phones, shipping and storing the products in our warehouses, and delivering them to our clients.

Leah: It is important for two reasons. Firstly, planting seasons, which are dependent on the onset of rains, do not start on specific dates each year. We start delivering at the start of the planting season because getting planting timing right ensures good harvests. Secondly, last-mile delivery is an important limb in our client satisfaction journey, and we take pride in fulfilling it. When we are consistent with our act, we keep our clients happy and in the program.

John: Without last-mile delivery, One Acre Fund wouldn’t create the same impact. We work for that farmer in a remote location who would otherwise not get quality planting supplies. When we are planning a delivery, we don’t consider the distance of the site from the warehouse; we just look at it as a site, with clients who expect to have their orders fulfilled.

What is your specific role in our last-mile delivery operations?

John: I am in the team responsible for actual delivery.

Leah: Whereas John’s role is more front-facing, I am in the planning and coordination side of things. I am responsible for managing inventory, coordinating with Procurement and Global Sourcing teams to source farmers’ orders. We order based on how many clients we enroll in a particular season and then ship and store them in our warehouses. Once we have the products, we begin to map out and simulate delivery scenarios to plan for contingencies.

John: Typically, I’ll take Leah’s plans and records and translate those into actual distribution. When executing delivery plans, I’ll generally confirm product quantities for a particular warehouse and tally those with what we are sending and ensure that a farmer gets exactly what they ordered by getting each parcel on the correct route. That way, we account for everything we received and avoid stray deliveries.

What does last-mile delivery look like in the One Acre Fund context?

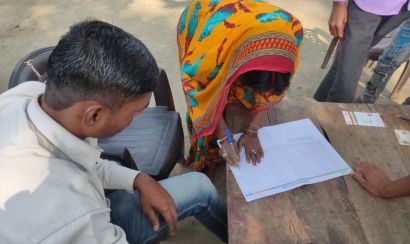

John: We deliver inputs to within two to three kilometers of a client’s home. We take inputs to various distribution sites from the warehouse — a school, church, or chief’s camp — where farmers pick up their orders. In Kenya alone, we deliver to over 2,500 delivery sites. We use geotagging software to pinpoint and monitor activity in each site to ensure the goods arrive and that farmers get what they ordered. When delivery starts, the products are already in our district warehouses. We work with large-capacity transporters who deliver seed, fertilizer, and other products to various sites. Where there are no roads, or they are impassable, we deliver using alternative modes of transport, like tractors, motorcycles, and donkeys, which can virtually go anywhere.

Leah: Just before the rains arrive, we create a routing delivery schedule based on our sites. We communicate specific days to the field team when inputs will arrive at each site so they, in turn, can communicate with farmers to come to pick them up. In a nutshell, we spend months sourcing the product and planning delivery, but the actual distribution work happens over several days. Everything builds up to a single but significant event.

How has COVID impacted our distribution model?

Leah: Last season (2020), we trialed delivering to individual farmers’ homes in two districts in Kenya. Although our motivation was to improve customer experience, it happened in a year of distance when we needed to adhere to COVID regulations like physical distancing and avoiding group meetings; this meant changing our typical delivery drops, where we deliver to a site and farmers from across that area come to pick up their orders. The pilot was a success and was very well received, and we’re now looking at ways we can refine and roll this delivery method out across all districts over the next couple of years.

In our desire to minimize the risk of coronavirus infections, we also began distributing earlier than usual and staggered delivery over several weeks where smaller groups could collect over a longer period. These changes to approach are something we are looking to keep over the long term.

John: COVID revealed a crucial vulnerability in our supply chain; we were compelled to react to something new that we could never have anticipated. Sometimes, especially in the early days of the pandemic, we had to work with extremely short deadlines, which we realized some of our suppliers could not meet. Going forward, we are refining our reaction time and putting plans in place to ensure the people we work with can be equally nimble in emergencies.

Over the past year, I’ve been stressed by what COVID has done. Because of the disruptions it brought, we have had to revise or shift some important deliverables that would otherwise have changed farmers’ lives. The costs of some processes have gone up because of the pandemic, which means we have overshot some budgets. There is an economic recession in Kenya, and there could be a global one that may affect our ability to serve farmers. I worry about not being able to continue serving farmers.

What lessons have you learned over the past year that you are carrying to the future or that could be useful for other organizations involved in last-mile delivery logistics?

Leah: Speaking generally, I am a lot more team-centric now than I was last year, and it is something I want to actively maintain. We drive results best by including everyone in decision-making, considering every point of view, and giving everyone a chance to contribute. We overcame some huge challenges this past year because we rallied together and believed in everyone’s abilities.

John: I’ve learned the value of practical business continuity plans because they mean the difference between surviving shocks and thriving and closing down.

What is the most satisfying thing about your job?

John: Oh, that is easy. I live for the impact we create in farmers’ lives. It is incredibly satisfying to see farmers’ lives improve season after season; it is one reason I joined One Acre Fund. Having worked for for-profit organizations before, the chance to drive positive social change is something I cherish. I recently saw a picture of a farmer’s house with half the roof done. She enrolled for iron sheets, but we ran out of those because there was a shortage of metal in the market when COVID restrictions came into force last year. I thought to myself, her roof is half done because the supplier ran out of iron sheets, not because we couldn’t provide iron sheets. We wake up every day not to profit but to impact lives; that is as great a reason as they come.

What advice would you give to someone looking to get involved in logistics?

John: Keep your ear to the ground. The world is changing rapidly, and logistics with it. Things like digitization, consumer trends, and preferences are realities in supply chain management that we cannot afford to take for granted; they define every aspect of our business lives. This is especially true because globalization means competition is never local, always global.

Leah: Contingencies, mitigation plans, and business continuity strategies are as necessary as operational plans. You must quickly adjust to emergencies and come out on top; it is the only way to survive and get on, whatever your industry.